Warehouses pose unique cleaning challenges for employees and janitorial staff. As large industrial facilities with heavy traffic of goods, people, and activity, they are susceptible to an almost never-ending accumulation of dust, dirt, smoke, vapors, grease, mould, bacteria, viruses, pests, and even fungi. These contaminants can pose health and safety hazards for both employees and customers.

Fortunately, having a strong, ongoing system for warehouse cleaning, along with the right cleaning tools and machines, can help your team keep your warehouse clean, safe, and operating at full capacity.

Running a clean, tidy warehouse can increase productivity, boost employee satisfaction, and enhance your reputation with customers and the community.

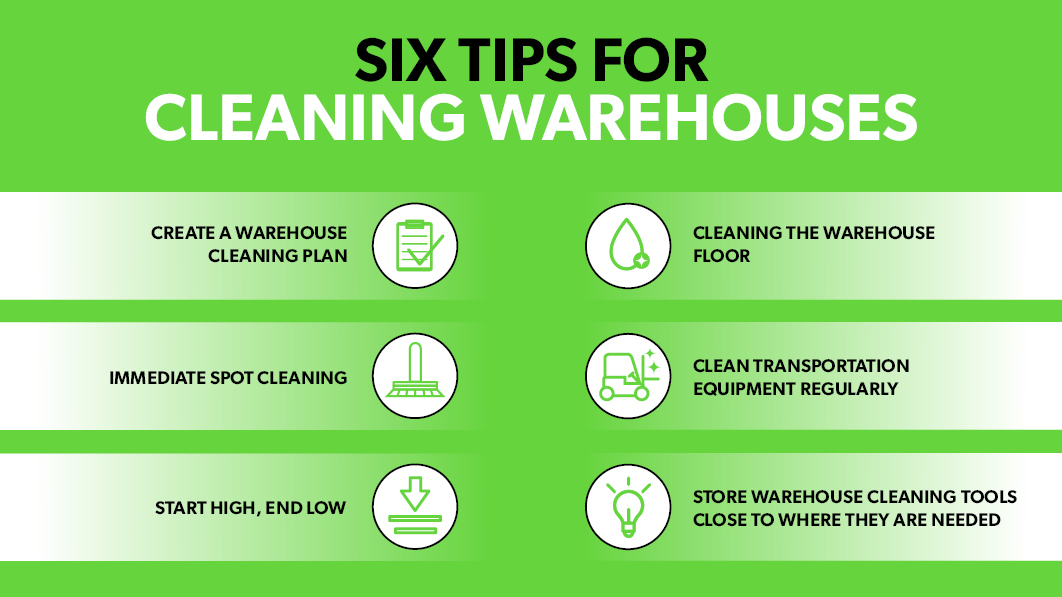

1. Create a Warehouse Cleaning Plan

Create a plan for each department or area of your warehouse. This plan should list each surface and item that needs to be cleaned. Determine when cleaning should take place, who will be responsible for cleaning, and then ensure that they have the correct cleaning tools to do the job properly. For instance, some of the areas that need cleaning include:

- Hard floors, carpeted floors and floor mats

- Shelves and racks

- Walls, ceilings, and windows

- Heating and cooling ducts

- Light fixtures

- Production equipment

- Restrooms

- Employee break rooms

- Office areas and furniture

- Entryways, outside areas and outside equipment

Putting the plan into a shared, electronic facilities management system calendar and assigning warehouse cleaning tasks to specific people can help ensure that each area of the warehouse is cleaned regularly.

2. Immediate Spot Cleaning

Even on the best days, spills and malfunctions can create even more of a mess than the daily dirt. It’s very important to clean up spills immediately to keep messes from spreading and enable work to resume quickly and safely.

3. Deep Cleaning Hard-to-Reach Areas

Cleaning systematically can enhance efficiency in the warehouse. This means cleaning high shelves and racks first, as dust and debris will succumb to gravity and fall to lower levels. This includes cleaning the heating and cooling system ducts before cleaning the areas below them.

Staff can then systematically work from higher to lower shelving and areas, ensuring all dust and debris is cleared from top to bottom, ending with the floors.

This can reduce the risk of injuries from falling items during the cleaning process. To ensure all debris is removed from high, hard-to-reach areas, use extension poles with duster heads and professional vacuum cleaners with extensions.

4. Cleaning the Warehouse Floor

In addition to cleaning higher areas before lower areas, make sure to move any pallets or movable equipment from the floor before cleaning to make it easier for your industrial ride-on scrubber dryer to move without any hindrance for thorough cleaning.

Keeping your warehouse floors clean is essential to worker safety and efficient operations.

Large-scale floor scrubber dryers can be used to remove grime and dirt, as well as grease from tire marks or spills that could cause working hazards.

5. Clean Transportation Equipment Regularly

Forklifts and other equipment used to move items indoors and outdoors should be cleaned often to reduce the amount of outside dirt that makes its way into the warehouse.

6. Store Warehouse Cleaning Tools Close to Where They are Needed

Each department should have its own cleaning tools stored close to where staff will use them. For example, each area could use a small wet and dry vacuum cleaner for daily spills and small-area clean-ups. “Backpack” vacuums are an excellent solution for smaller areas and low shelves. Telescoping extension poles can be fitted with a variety of duster heads. Industrial-sized floor scrubber dryers can cover larger areas. For floors that frequently collect oil and grease stains, trolleys equipped with wringers to be used in combination with microfibers and detergent solutions are very useful.

IPC develops cleaning tools and solutions, especially for cleaning warehouses around the world. For expert advice and cleaning equipment, please contact us, and look through our product pages to see the wide variety of tools used to keep warehouses and industrial settings clean.